Mark DiVecchio's O-Gauge Train Layouts

3D Printed

White Tower Restaurant

This Page last updated on

.

(For more 3D prints, click

here)

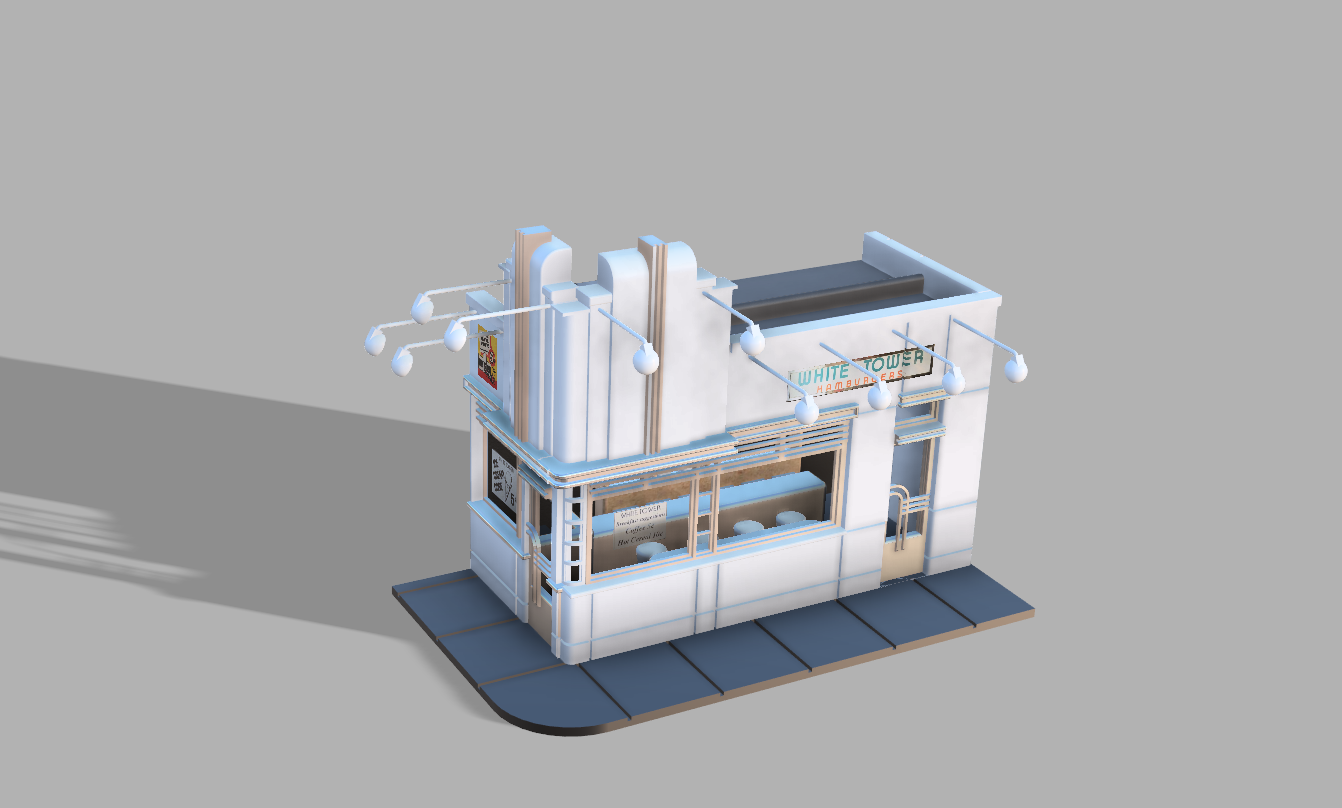

Designing

and Printing a 3D White Tower Restaurant

I've been carrying

around the White Tower Restaurant article from the March 1993 issue

of Model Railroader for just about 25 years. I was

captivated by

Michael Tylick’s

model from the first time I saw it but I did not

even come close to having the skills to construct it. So now I have

something to help me, 3D printing. Using the Autodesk

Fusion 360

program and the drawings in the article, I designed, printed, painted

and assembled a reasonable version of the White Tower restaurant for

my layout.

My

journey through

this project was really three journeys; selecting a 3D printer and

learning how to use it, finding a computer program to develop the

model, and finally, printing, painting and assembling the

model. Mike’s original model and my copy are O scale.

The

completed White Tower Restaurant

Finding a Printer

I’ve learned that 3D printers come in three sizes; cheap -

$150-$250, reasonable - $700-$1000 and expensive - $2000-??. It boils

down to how much tinkering you can (or want) to do. The cheap printers,

mostly on eBay, are kits from China. They work well enough but their

assembly and adjustment is difficult. The reasonably priced printers

are kits at the lower end and fully assembled at the upper end. More

thought has been put into the engineering of the printer. Assembly and

adjustment are easier than the cheap models. The expensive printers are

fully assembled, adjusted and tested. They work out of the box.

All will be able to print the White Tower Restaurant.

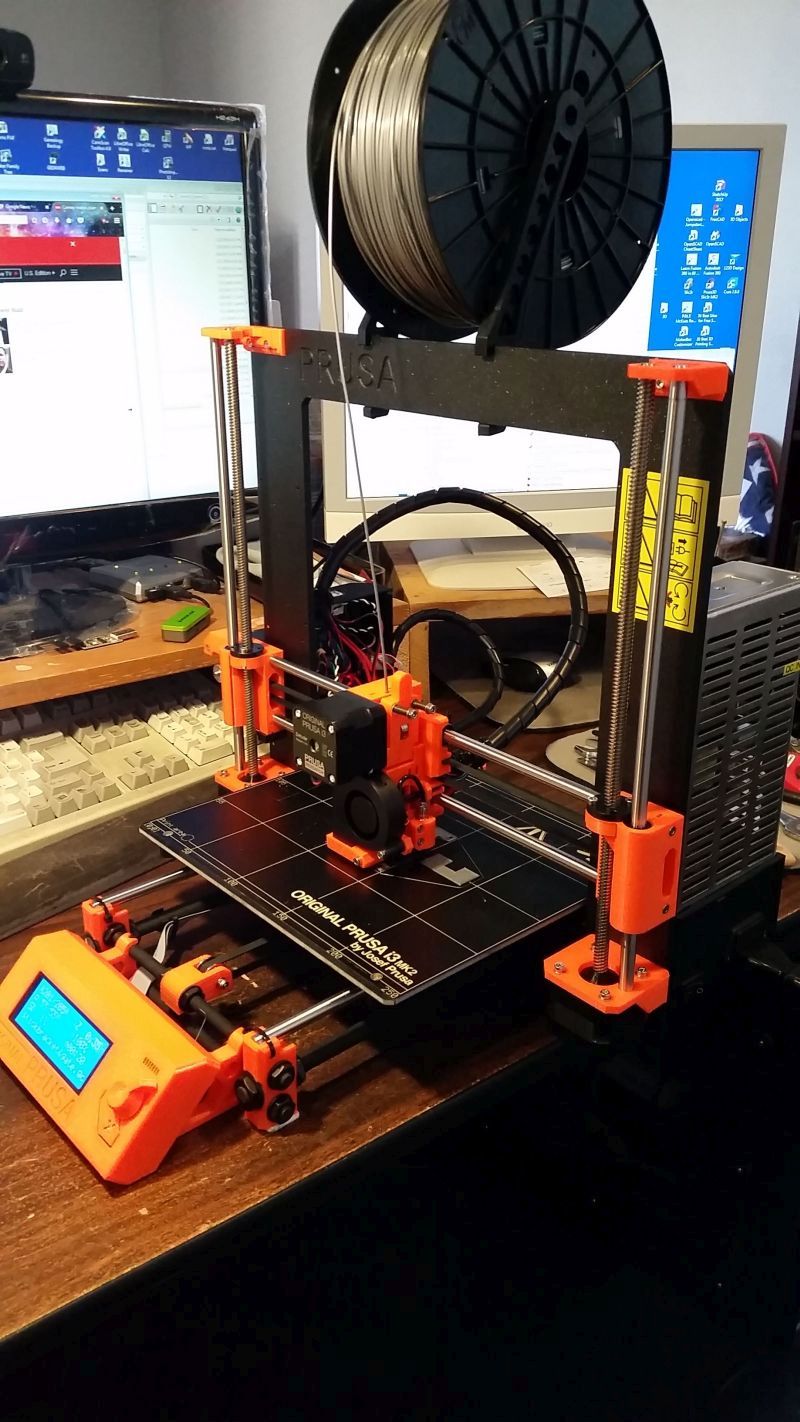

I selected a printer from Prusa Research. It was their model Original

Prusa i3 MK2S. It was a kit which I assembled and adjusted.

Anyone with the

mechanical and electrical skills to build a model train layout will be

able to successfully get this printer working.

3D printers can use many different types of material. I used a type of

plastic called PLA (Polylatic Acid). I was able to use plastic solvent

to assemble the model.

Here is a photo of my printer printing some small parts of a project I

used to learn how to use the printer.

My Original Prusa I3 MK2S

3D Printer

Finding a Program

There are many free programs available. FreeCAD, OpenSCAD, Tinkercad

and SketchUp are four. These programs are fine for simple structures. I

used them to construct small objects as I was learning how to use the

printer.

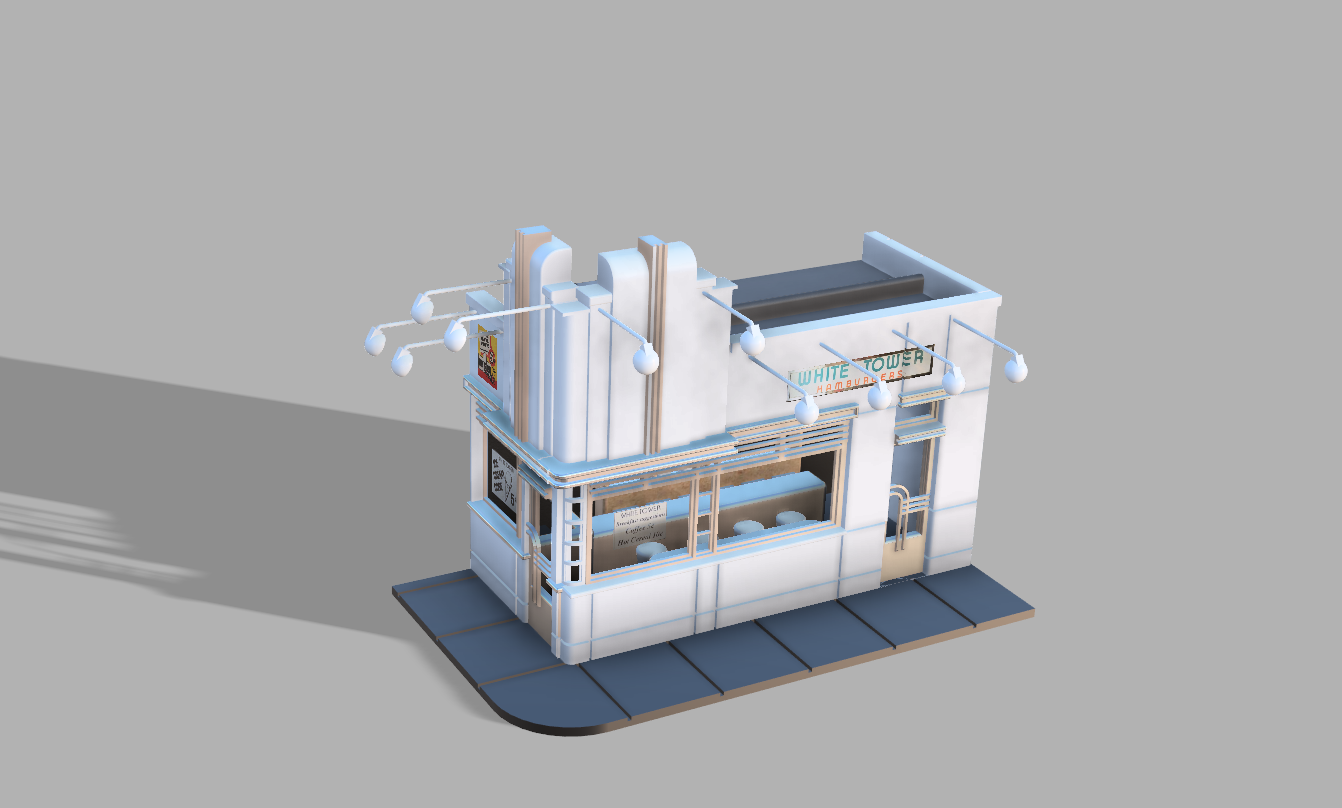

I used a fifth program to actually develop the model, Autodesk Fusion

360. This program is free for hobbyist users. It is a feature rich

program with every design function you will ever need. There certainly

was a learning curve involved. I learned the program as I developed the

model. When I got to a point where I needed to do something

and

didn’t know how to do it, I googled it or checked one of the

hundreds of tutorials on YouTube.

Starting on the front wall using Fusion 360

Front and side walls completed

The completed model in the Fusion 360 program.

Printing, Painting and Assembling

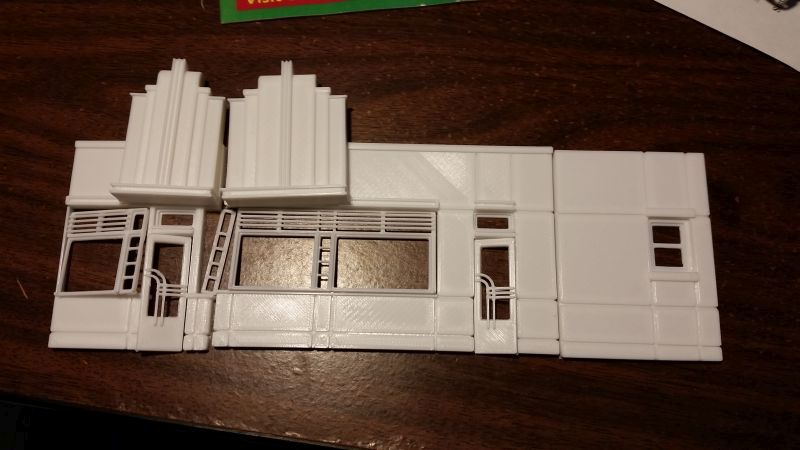

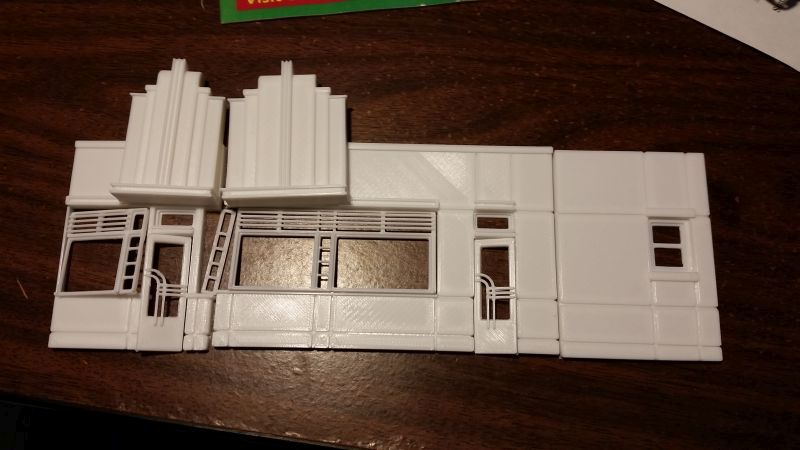

I broke my model down into about 20 pieces for printing. After some

experience with 3D printing, I learned that flat, low profile pieces

print the best. Each wall, door, and window were printed as separate

pieces. Some filing and sanding was required.

I then painted the sections. If I were to do this project

again,

I would be more careful to break the model into pieces that were each

one color. Doing that would let me print the trim using an

aluminum/silver PLA

and avoid any painting. Except for some details, there were only two

colors involved – for the walls and towers, I used MicroLux

Reefer White and for the window framing, door handles and

tower detail,

I used Createx

Wicked Aluminum. I brush painted everything.

Then, finally, I glued the walls, base and roof together using model

airplane glue.

Signs were printed on my color inkjet printer from images found on the

web and in Mike’s original article. I used thin plastic for

the window "glass".

Printed pieces making up the front, side and rear walls before assembly

Assembled model on my workbench

I originally did not design an interior but after I saw the model

assembled, I realized that it needed one. I designed and built a simple

interior that, through the windows, looked “good

enough”.

The interior generally follows what was in the

1993 MR article but with much less detail. Everything, except some of

the

tiny detail parts on the counter and shelves, was printed on my printer.

The guy in my White Tower behind the counter is a street sweeper from a

Model Power "Station Service Crew" #6050. I don't remember right off

where the other two people come from. Other 1:48 people makers are MTH,

Bachmann, Artista, Woodland Scenics, Life-Like, Preiser and K-Line.

Simple Interior

I added LEDs for interior lighting. Here is early morning at the White

Tower. The cop was happy because he got his morning donut. I did not

try to

light the exterior but I think it needs it and I will have to work out

something.

Completed model on my layout

This project gave me an avenue to learn a lot about 3D printing and its

application to my model train layout. There was a lot to learn but

I’m pleased with the results.

My Fusion 360 design file and the 3D printer “.stl”

and

“.gcode” files are available in this zip file:

White

Tower.zip.

The design files are copyright by Mark DiVecchio. You can use,

redistribute and/or modify it under the terms of the GNU

General

Public License as published by the Free Software Foundation,

either version 3 of the License, or (at your option) any later version.

See <http://www.gnu.org/licenses/>.

Summary

It was a lot more work than

I thought. One big part was learning the Fusion 360 program well enough

to be effective.

This project showed the limitations of 3D printing and the advantages.

The small features were difficult to print. The window bars and the

curved door handles were a challenge. The floodlight and support arm

were the most difficult. I printed them at least a dozen times before I

found an orientation and support/raft structure under it that finally

gave me more than just a blob of PLA on the print bed. I did this

design in inches since that is how the original model was done. The

smallest feature that I

was able to print was 0.04". The round arms holding up the lights and

the square bars on the windows and doors are 0.04" across.

This

photo is my print of the 10 lamps needed.

The really big advantage of the Fusion 360 program is being able to

change

dimensions without having to first cut plastic. Fusion 360 lets you go

back an unlimited number of steps and change a dimension. Then it moves

forward through your subsequent steps and that new dimension is applied

automatically.

The "Combine" function in Fusion 360 was the most helpful. I built up

each

section of the building based on the drawings in the Model Railroader

article. I forgot to consider that some of sections from different

views will overlap when the model is assembled. The combine function

let me take two walls, for example, put them together in their actual

orientation and then the program would exactly cut out of one wall just

enough plastic so that the two walls will glue together perfectly. This

really helped on the front and side towers.

I did have to paint the building white. The white PLA that I had was

too translucent. I had bought it to do the windows on my P&LE

Locomotive Shop. Next time (Ha!) I would use a more opaque

white and an aluminum/silver PLA to save painting.

To do that, I would have to change how I "chopped" up the building for

printing. Next time, I would chop it at the split between the white and

the aluminum/silver colors. Then print each piece with the

appropriate color PLA.

The floodlights and support arms turned out to be really delicate. I've

broken about 8 of them trying to get the 10 I needed. Next time, I

would print them with 100% infill to try to make them more sturdy. I

did not glue them into their mounting holes as I know I break 1

or 2 each time I touch the building.

I printed at 0.2mm but again, next time, I might do 0.1mm. That will

double the print time so I'm not convinced. I did print my Locomotive

Shop at 0.1mm. The Shop had 7 wall sections with two pieces each and

each piece

took between 6-8 hours to print (you can do the math). The Locomotive

Shop wall had

really tiny bricks and tiny grout lines in between.

Still to do

The outside lights and support arms need to be

painted aluminum.

Actually light up the outside walls.

References

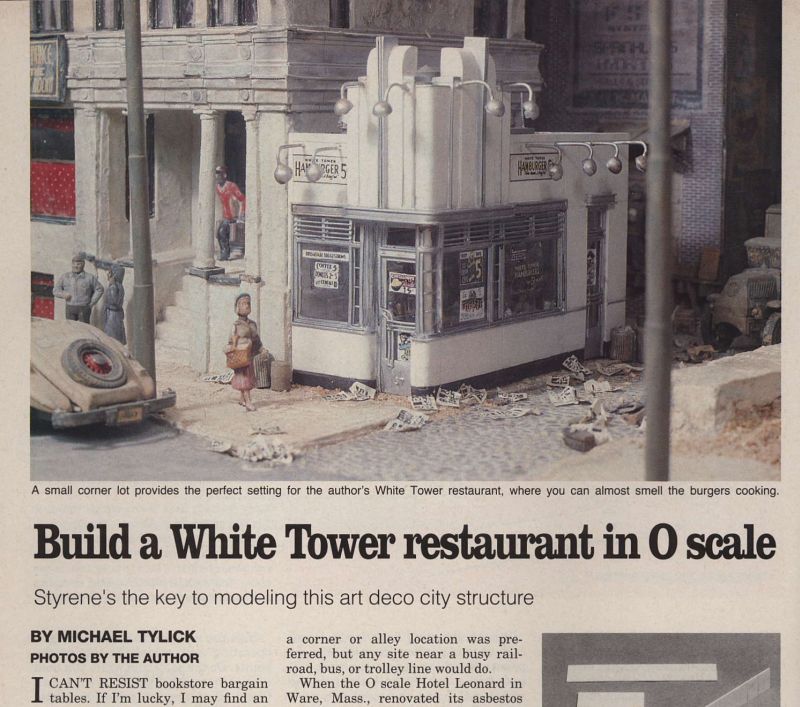

Here is a photo from Mike’s 1993 Model Railroader article:

Email with Mike Tylick

8 Dec 2017

Michael,

I've been carrying around your White Tower article from the March 1993

issue of MR for just about 25 years. I was captivated by your model

from the first time I saw it but I did not even come close to having

the skills to construct it.

So now I have something to help me, 3D printing. Using the Fusion 360

program and the drawings in your article, I printed a reasonable

version of your White Tower restaurant for my layout. My interior is

much less detailed though.

I thought you might enjoy seeing this.

Mark |

9 Dec 2017

Wow - it must

have taken quite a bit of work (and printing material) to

make this. What a neat job. Perhaps you should try

to sell

these.

Thanks for

sending this to me.

Mike T

www.raildesignservices.com

|

This site prepared and maintained by Mark DiVecchio

email : markd@silogic.com

SD&A

HOME

Mark's Home Page

The DiVecchio

genealogy home page

The Frazzini

genealogy home page

This site will be under construction for a while.